VBH Series – Walcarki 4-wałkowe

Niemal stuletnie doświadczenie produkcji maszyn do gięcia i współpraca z naszymi klientami są zawarte w naszych 4-rolkowych walcach do gięcia blach VBH. VBH to najlepsza maszyna zarówno do gięcia cylindrycznego, jak i stożkowego. Główne cechy naszych rolek VBH to większa siła docisku dolnego walca (dla krótkich płaskich końców i optymalnego gięcia wstępnego) oraz wyższy moment napędowy (dla procesu jednoprzebiegowego) w celu zwiększenia produktywności. Optymalna kombinacja dla tych, którzy szukają wydajności na najwyższym poziomie.

- General Details

Walcarki przekraczające oczekiwania użytkownika?

To proste: zupełnie nowa seria VBH została stworzona z przekonania, że każda funkcja,

każda innowacja musi być ukierunkowana na pomoc w zwiększaniu zysków.

To skłoniło naszych inżynierów do zaprojektowania następnej generacji walców do blachy,

koncentrując się na czterech kluczowych obszarach wydajności maszyny:

WYTRZYMAŁOŚĆ: Liniowe prowadnice ślizgowe i system wsparcia rolek z wieloma łożyskami.

MOC: Jednostka redukująca wysoki moment obrotowy dla zmniejszonej liczby przejść walcowania.

PRECYZJA: Cyfrowe sterowanie równoległością walców za pomocą zaworów proporcjonalnych.

STEROWANIE: Bezstopniowa regulacja prędkości rolek, bezstopniowa regulacja nacisku docisku dolnego

walca centralnego, tryby pracy kalibracji , rozbudowany system diagnostyki i …

to tylko niektóre z funkcji, którymi można sterować bezpośrednio z mobilnego panelu operatora, po prostu przesuwając palcem .

Produktywność – efektywność Zwijarki do blach serii VBH: elastyczne, wszechstronne, mocne i wydajne.

Większa produktywność i wysoka wydajność w standardzie.

Najlepsza kontrola procesu Bezstopniowa regulacja prędkości, bezstopniowa regulacja siły docisku i tryb pracy kalibracji,

to tylko niektóre cechy, którymi można sterować z mobilnego panelu operatora, po prostu przesuwając palcem.

Elastyczność – precyzja Od aplikacji warsztatowych po produkcję wielkoseryjną,

Parmigiani VBH przekroczy Twoje oczekiwania dotyczące jakości i precyzji.

- Features

Get more with linear guides

ALG System Antifriction Linear Guides

The linear guides design is the only system that can grant the necessary machine stiffness and the perfect geometry for all kind of bending operations.

The linear design allows a compact geometry of the machine (“minimum centerline distance between the two side rolls” impossible to obtain with the swinging design) that it is essential for the bending precision and accuracy.

The linear design allows to work in the best and ideal geometrical conditions when rolling high yield strength materials, reducing the shell spring back reopening effect and also allows to obtain much smaller bending diameters when compared with the swinging design.

No friction – less than swing design

Direct loads to the plate

Less vertical power on top roll

Lower bending diameterBuilt for heavy works

HMB System Heavy Multiple Bearings

Each bending roll is supported by 4 heavy-duty self-aligning spherical roller bearings (double raw type).

Each bearing is oversized in order to withstand the whole bending load.

Thanks to the HMB exclusive design, with four oversized bearings fitted into a swiveling housing, the roll can freely deflects along it’s full width during the rolling process.

This guarantees an optimal distribution of the load on the supports even during the cone rolling process and increase the machine reliability and life.

Moreover, the multi bearing system with swiveling housings design greatly reduces the maintenance and the need for lubrication (permanent lubrication).

The powerful and reliable choice

Full frame extended design

The most heavily sized frame you can find in the market.

Unlikely slim frames covered with thin thickness plates that you can find on all machines in the market our frame design looks definitively oversized.

The exclusive full frame design withstands all bending forces and guarantees stiffness and performances through the years.

This unique machine frames, with extended design for added rigidity and strength, are welded fabrication.

After welding all frames are stress relieved and then machined on cnc milling machines.

Friction free – Maintenance free

Friction free – Maintenance freeAST System Anti-friction sliding technology

Each Rolls supports with machined anti-friction material in sliding area.

This system drastically reduce the maintenance and the sliding friction is lower than in a planetary machine.

More power – More torque

HTT System High transmitted torque

The rolls driving is realized by independent hydraulic motors via planetary gear transmission directly coupled to each driven roll.

The rolls driving is realized by independent hydraulic motors via planetary gear transmission directly coupled to each driven roll.The independent rolls hydraulic drive assures and automatic speed compensation between the top and lower rolls and an optimal distribution of the torque on each roll during the working phase.

The HTT system allow the best plate feeding and the highest driving torque of any competitive machine.

A winning combination for those looking for performance of the highest level.

- Technology

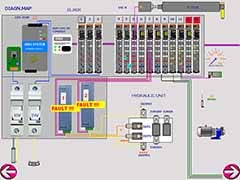

i-Diagnostic®

ACTIVE EXTENDED DIAGNOSTIC

Everything is under control Are you loosing with your actual equipment production hours and days checking around the machine which connection wire, Plc card, push-button or fuse is faulty?

Are you loosing with your actual equipment production hours and days checking around the machine which connection wire, Plc card, push-button or fuse is faulty?Forget this kind of problems with PARMIGIANI i-Diagnostic system for immediate fault detection.

The i-Diagnostic is a revolutionary diagnostic system that supervises all the main functions of the machine, with an easy to use and intuitive control panel interface.

From the screen you control almost all electrical connections around the machine; all PLC modules; all micro-switches (You can check also if they are engaged /energized or not) and more….

Instantaneous fault detection instead of troubleshooting

Detailed information on type and location of the faultPPS Hydrotronic®

PARMIGIANI PARALLELISM SYSTEM

Lifetime precision When you want to move to precision rolling, look to Parmigiani

When you want to move to precision rolling, look to ParmigianiThe PPS is the most advanced parallelism system today available on the market.

The rolls parallelism in a plate bending machine is the key factor for the production accuracy.

The capability to maintain the precision across the years is also another critical point.

For this reason we employ the best of the today available technology: digital control system and hydraulic flow control via proportional valves.

We have designed a system totally insensible at the wear that will give you years and years of trouble free operation, keeping the machine positioning precision like the first day!

The top and bottoms rolls parallelism is fully controlled by a digital “high speed” FIELD BUS system.

The package includes also a set of hydraulic proportional valves with high performance digital control cards, matching the high speed of the FIELD BUS system.

This digital technology (the loop control is 20 times faster than PLC-based electronic controls) joined with the hydraulic proportional valves, provides a parallelism precision of about 0,1 mm.

Digital control technology with hydraulic proportional valves

Parallelism precision 0,1 mm

FACILE®

ADVANCED WIRING SYSTEM

Plug and play technology

Do It by yourself

“Assemble and plug in – that’s all!”

Quick and simple plug connections replace elaborate wiring.

- Avoids wiring errors

- Shortens start-up time

- Quick swapping of cables

The wiring of the machine is achieved by Plug and Play connectors and digital distributors.

The cabling system with connectors is more reliable over time, totally insensitive to environmental contamination and vibration and allows for quick and easy maintenance with unqualified personnel

With our FACILE® Plug and Play system you can change a wiring connection (to the hydraulic valves or the encoders or potentiometers, to a micro-switch etc…) with pin plug connector, without unscrewing any electrical wire.

Same procedure for all PLC modules! Without the need of a skilled electrician!

With the purpose of increasing your independence from third parties all software are loaded in static memory cards, (like the ones used in digital video camera) and not in volatile Eprom! This means practically that you will never lose the software, even in case you will need to change the Plc unit.

Our plug-play system is a military approved technology!

Maximum reliability.

Quick and easy maintenance without specific skill.

Hi-Tech Hydraulic

ADVANCED HYDRAULIC SYSTEM

Infinitely variable adjusting speeds

Infinitely variable bending pressure The hydraulic system is the operative core of your VBH: it runs everything from the bending rolls drive to the bending rolls movement, tilting and all other machine attachments.

The hydraulic system is the operative core of your VBH: it runs everything from the bending rolls drive to the bending rolls movement, tilting and all other machine attachments.This is why we invested a lot in research and development, for give you a smooth, precise and highly responsive system.

Through the digital control system we control, by dedicated hydraulic proportional valves, the pressure and flow in order to allow you to select the most convenient speed during each production step (vs. other brands machines that give you only one or two selectable speeds) and the maximum central lower roll pinching force in order to adapt it to the characteristics of the plate being worked.

The possibility to select low pressures for thin plates widely extend the range of the machine.

With the infinitely variable pressure and the infinitely variable speed adjustment the operator will have full control of the process in any bending situation.

- Controls

Everything is under control

Dedicated controls from PARMIGIANI for plate rolling cover an entire range of applications.

All softwares are in house developed by Parmigiani technicians with great experience in plate rolling.

From the simple, compact DIGIMATIC control to the STRADIVARI (unlimited number of axis) there’s a PARMIGIANI control for nearly every application.

Parmigiani NC and CNC controls are 100% in house developed.

Controls are an essential requirement for executing precision rolling applications. Select the SAVE&BEND with its 10.4” display or the FAST with a 15” display or the STRADIVARI with a 19″ display. They function just like a tablet with touch-screens: navigating through the options is simplified via menus, shortcuts and with context-sensitive help.

DIGIMATIC®

DIGIMATIC®- 7” full color display, touch – screen

- N° 6 digital read-outs, for Central Lower and side rolls. With 2 digital read-outs for each bending roll the operator can read exactly the inclination of the roll during conical bending.

- N° 1 digital read-outs, for Central Lower roll pinching pressure

- 7 Controlled Axis

- It’s possible to create different programs, saving the the pinching pressure of the lower roll and the positions of Lower and Side rolls for the automatic positioning (step by step)

- Storage Memory Capacity: up to 500 programs of 26 step each.

SAVE & BEND®

SAVE & BEND®NC Control type PARMIGIANI “SAVE and BEND”:

The entry level NC with 9 controlled axis, for fully automatic working mode.

- 10,4” color display, touch – screen

- 9 Controlled Axis (it can be upgraded up to 16 axis)

- Two possible ways of programming: Editing and Play-back mode

- Storage Memory Capacity: up to 1.000 programs of 50 step each

FAST®

FAST®CNC Control type PARMIGIANI “FAST”:

with Automatic program mode for single radius shapes: the control automatically creates the complete bending program, simply entering the shell data (radius, thickness, width, type of material), with all the sequence for obtaining the required shape. If necessary the program theoretically calculated by the control can be optimized by the operator.

- 15” full color display, touch – screen

- 9 Controlled Axis (unlimited upgradeable number of axis)

- Three possible ways of programming: Aided, Editing and Play-back mode

- Storage Memory Capacity: up to 5.000 programs

STRADIVARI with 3D ROLLCAD®

STRADIVARI with 3D ROLLCAD®BE INDEPENDENT FROM OPERATOR SKILL.

Easy to use. Easy to program. Accuracy. Productivity.STRADIVARI® software has been in house developed by Parmigiani R&D internal team of experts; technicians with long experience in plate rolling, having in mind two major targets:

- Easy to use also without particular CNC experience,

- Maximum flexibility in order to be largely independent from the operator’s skill.

3D ROLLCAD®

3D ROLLCAD®The STARDIVARI® now incorporates the 3D-ROLLCAD®, a real 3D CAD SOFTWARE, fully integrated in the CNC, that automatically creates the bending sequence starting from a drawing. This means that you are no more limited to pre-set standard shapes (wizard)!

Just draw the shape in the 3D-ROLLCAD®, and you will have the full bending sequence automatically generated by the software.

But we have done more: a powerful macro with conversational data input that allows to draw shapes in 3D-ROLLCAD® without previous cad experience.

Of course the STRADIVARI® can still work in the old way: starting from a menu of standard shapes (cylindrical, oval, polycentric, bucket ect.) and simply entering the shell data -radius, thickness, width, type of material- the control creates automatically the 3D drawing of the workpieces and the complete bending program with all the necessary bending steps. If necessary the program theoretically calculated by the control can be easily optimized by the operator.

- Options

Great Options and Accessories

Even though your Parmigiani VBH in standard configuration is delivered with a package of features that usually are not available – even as options- in the other machines (like FACILE, i-diagnostic, Calibration working mode, Servodinamic Active Control with infinitely variable positioning speeds of the bending rolls and active pressure control of the lower roll…) our R & D department has designed a wide range of accessories for special bending applications, like the Hydraulic cambering device for central lower roll with variable intensity for working with thin and long plates, gantry loaders, unloading devices etc. in order to increase productivity and quality of the finished for special materials.

Servodinamic Active Controls

Pressure and speed control of the and top and lateral support devices.

Side and Top supports with variable positioning speed

The upper and the side plate supports device are supplied linked with our SERVODYNAMIC ACTIVE CONTROL SYSTEM. SERVODYNAMIC because they have variable positioning speed, with high speed for fast positioning and low speed for creep adjustment and soft contact with the plates. ACTIVE, because you can control on a digital read-out placed on the control panel their working pressures.