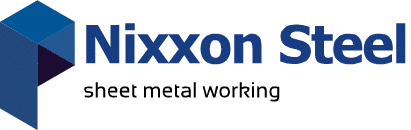

TBH Series – Walcarki 3-wałkowe

TBH to walce do blachy o konstrukcji piramidalnej z niezależną regulacją dwóch dolnych rolek na nachylonych prowadnicach ślizgowych. Pozwala to na wstępne zaginanie i zwijanie obu krawędzi płyty przy tylko jednym włożeniu (nie ma potrzeby wyjmowania i obracania płyty). Napęd z trzema rolkami zapewnia najlepsze podawanie płyt również podczas walcowania cienkich blach, a duży prześwit między rolkami górnymi i dolnymi zwiększa możliwości maszyny.

- General Details

Walce TBH są wyposażone w wyjątkowy Parmigiani Parallelism System (PPS) do kontroli równoległości rolek (typu zamkniętego pierścienia).

PPS zapewnia maksymalną precyzję pozycjonowania rolek także po kilku latach intensywnej pracy.

Liniowe prowadnice ślizgowe z materiałem przeciwciernym (system AVG).

(Brak konieczności konserwacji; Wysoka ładowność i nośność; Gładkie i stabilne ustawienie).

Wszystkie rolki, zamontowane na łożyskach baryłkowych, są napędzane przez oddzielny silnik hydrauliczny dla każdej rolki.

Giętarki TBH wyposażone są w system wielożyłowy, który gwarantuje najwyższą niezawodność nawet przy intensywnej produkcji i gięciu stożków.

Odkryj wyjątkowe cechy serii TBH:

Odkryj wyjątkowe cechy serii TBH:- Sztywna konstrukcja ramy bez sił przenoszonych na fundamenty

- Konstrukcja z pełną ramą zapewniająca maksymalną sztywność i precyzję

- Okablowane kablami świetlnymi chroniącymi przed zakłóceniami elektromagnetycznymi

- Centralny panel sterowania, lekka konstrukcja ułatwiająca obsługę

- Rolki wykonane z odkuwek stalowych o wysokiej wytrzymałości, o dużej średnicy i lekkim wygięciu

- Rama maszyny z prowadnicami liniowymi do przesuwania rolek

- Wytrzymały system wielożyłowy z 4 łożyskami baryłkowymi na każdą rolkę

- Przesuwne podparcie z wytrzymałego materiału przeciwciernego bezobsługowe

- W pełni hydrauliczny napęd z automatyczną kompensacją prędkości

- Cyfrowe sterowanie równoległością rolek za pomocą zaworów proporcjonalnych. Precyzja 0,1 mm (0,004 ”)

- Wytrzymałe łożysko zwrotne z czterema punktami zapobiegającymi ugięciu dla maksymalnej sztywności

- Bezstopniowa regulacja prędkości rolek oraz panel dotykowy

- Solidna i sztywna konstrukcja ramy zapewnia maksymalny opór podczas toczenia stożka

- Features

With the TBH Series we exceed your expectations.

How we exceed your expectations? It’s simple: The all-new TBH Series was created from the belief that every feature, every innovation, must be focused on helping you grow your bottom line. This led our engineers to design the next generation of plate rolls, concentrating on four key areas of machine performance:

STRENGTH: Linear sliding guides and multiple bearings rolls support system.

POWER: High torque reduction unit for reduced number of rolling passes.

PRECISION: Digital control of the rolls parallelism with proportional valves.

CONTROLS: Infinitely variable rolls adjustment speeds, Infinitely variable central lower roll pinching pressure, shell calibration working modes, extended i-diagnostic system… are only some of the features that you can control directly from the operator mobile panel, just moving a finger.

Get more with linear guides

ALG System Antifriction Linear Guides

The linear guides design is the only system that can grant the necessary machine stiffness and the perfect geometry for all kind of bending operations.

The linear design allows a compact geometry of the machine (“minimum centerline distance between the two side rolls” impossible to obtain with the swinging design) that it is essential for the bending precision and accuracy.

The linear design allows to work in the best and ideal geometrical conditions when rolling high yield strength materials, reducing the shell spring back reopening effect and also allows to obtain much smaller bending diameters when compared with the swinging design.

No friction – less than swing design

Direct loads to the plate

Less vertical power on top roll

Lower bending diameterBuilt for heavy works

HMB System Heavy Multiple Bearings

Each bending roll is supported by 4 heavy-duty self-aligning spherical roller bearings (double raw type).

Each bearing is oversized in order to withstand the whole bending load.

Thanks to the HMB exclusive design, with four oversized bearings fitted into a swiveling housing, the roll can freely deflects along it’s full width during the rolling process.

This guarantees an optimal distribution of the load on the supports even during the cone rolling process and increase the machine reliability and life.

Moreover, the multi bearing system with swiveling housings design greatly reduces the maintenance and the need for lubrication (permanent lubrication).

The powerful and reliable choice

Full frame extended design

The most heavily sized frame you can find in the market.

Unlikely slim frames covered with thin thickness plates that you can find on all machines in the market our frame design looks definitively oversized.

The exclusive full frame design withstands all bending forces and guarantees stiffness and performances through the years.

This unique machine frames, with extended design for added rigidity and strength, are welded fabrication.

After welding all frames are stress relieved and then machined on cnc milling machines.

Friction free – Maintenance free

Friction free – Maintenance freeAST System Anti-friction sliding technology

Each Rolls supports with machined anti-friction material in sliding area.

This system drastically reduce the maintenance and the sliding friction is lower than in a planetary machine.

More power – More torque

HTT System High transmitted torque

The rolls driving is realized by independent hydraulic motors via planetary gear transmission directly coupled to each driven roll.

The rolls driving is realized by independent hydraulic motors via planetary gear transmission directly coupled to each driven roll.The independent rolls hydraulic drive assures and automatic speed compensation between the top and lower rolls and an optimal distribution of the torque on each roll during the working phase.

The HTT system allow the best plate feeding and the highest driving torque of any competitive machine.

A winning combination for those looking for performance of the highest level.

- Technology

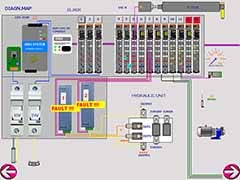

i-Diagnostic®

ACTIVE EXTENDED DIAGNOSTIC

Everything is under control Are you loosing with your actual equipment production hours and days checking around the machine which connection wire, Plc card, push-button or fuse is faulty?

Are you loosing with your actual equipment production hours and days checking around the machine which connection wire, Plc card, push-button or fuse is faulty?Forget this kind of problems with PARMIGIANI i-Diagnostic system for immediate fault detection.

The i-Diagnostic is a revolutionary diagnostic system that supervises all the main functions of the machine, with an easy to use and intuitive control panel interface.

From the screen you control almost all electrical connections around the machine; all PLC modules; all micro-switches (You can check also if they are engaged /energized or not) and more….

Instantaneous fault detection instead of troubleshooting

Detailed information on type and location of the faultPPS Hydrotronic®

PARMIGIANI PARALLELISM SYSTEM

Lifetime precision When you want to move to precision rolling, look to Parmigiani

When you want to move to precision rolling, look to ParmigianiThe PPS is the most advanced parallelism system today available on the market.

The rolls parallelism in a plate bending machine is the key factor for the production accuracy.

The capability to maintain the precision across the years is also another critical point.

For this reason we employ the best of the today available technology: digital control system and hydraulic flow control via proportional valves.

We have designed a system totally insensible at the wear that will give you years and years of trouble free operation, keeping the machine positioning precision like the first day!

The top and bottoms rolls parallelism is fully controlled by a digital “high speed” FIELD BUS system.

The package includes also a set of hydraulic proportional valves with high performance digital control cards, matching the high speed of the FIELD BUS system.

This digital technology (the loop control is 20 times faster than PLC-based electronic controls) joined with the hydraulic proportional valves, provides a parallelism precision of about 0,1 mm.

Digital control technology with hydraulic proportional valves

Parallelism precision 0,1 mm

FACILE®

ADVANCED WIRING SYSTEM

Plug and play technology

Do It by yourself

“Assemble and plug in – that’s all!”

Quick and simple plug connections replace elaborate wiring.

- Avoids wiring errors

- Shortens start-up time

- Quick swapping of cables

The wiring of the machine is achieved by Plug and Play connectors and digital distributors.

The cabling system with connectors is more reliable over time, totally insensitive to environmental contamination and vibration and allows for quick and easy maintenance with unqualified personnel

With our FACILE® Plug and Play system you can change a wiring connection (to the hydraulic valves or the encoders or potentiometers, to a micro-switch etc…) with pin plug connector, without unscrewing any electrical wire.

Same procedure for all PLC modules! Without the need of a skilled electrician!

With the purpose of increasing your independence from third parties all software are loaded in static memory cards, (like the ones used in digital video camera) and not in volatile Eprom! This means practically that you will never lose the software, even in case you will need to change the Plc unit.

Our plug-play system is a military approved technology!

Maximum reliability.

Quick and easy maintenance without specific skill.

Hi-Tech Hydraulic

ADVANCED HYDRAULIC SYSTEM

Infinitely variable adjusting speeds

Infinitely variable bending pressure The hydraulic system is the operative core of your VBH: it runs everything from the bending rolls drive to the bending rolls movement, tilting and all other machine attachments.

The hydraulic system is the operative core of your VBH: it runs everything from the bending rolls drive to the bending rolls movement, tilting and all other machine attachments.This is why we invested a lot in research and development, for give you a smooth, precise and highly responsive system.

Through the digital control system we control, by dedicated hydraulic proportional valves, the pressure and flow in order to allow you to select the most convenient speed during each production step (vs. other brands machines that give you only one or two selectable speeds) and the maximum central lower roll pinching force in order to adapt it to the characteristics of the plate being worked.

The possibility to select low pressures for thin plates widely extend the range of the machine.

With the infinitely variable pressure and the infinitely variable speed adjustment the operator will have full control of the process in any bending situation.

- Options

Rolls induction hardening and heat treatment.

Rolls induction hardening and heat treatment.- Cone bending device.

- Fully hydraulic upper plate support device.

- Fully hydraulic side plate support devices.

- Infinitely variable rolling speed.

- Infinitely variable bending pressure.

- Heat exchanger for cooling the hydraulic oil.

- Increased (Turbo) rolling speed.

- Extended rolls for assembling profile bending dies.

- Set of profile bending dies.

- NC control: SAVE&BEND .

- CNC control: FAST and STRADIVARI 3-R .

- Wireless control.

- Special operating voltage or special electrics.

- Remote assistance via modem.

- Gallery