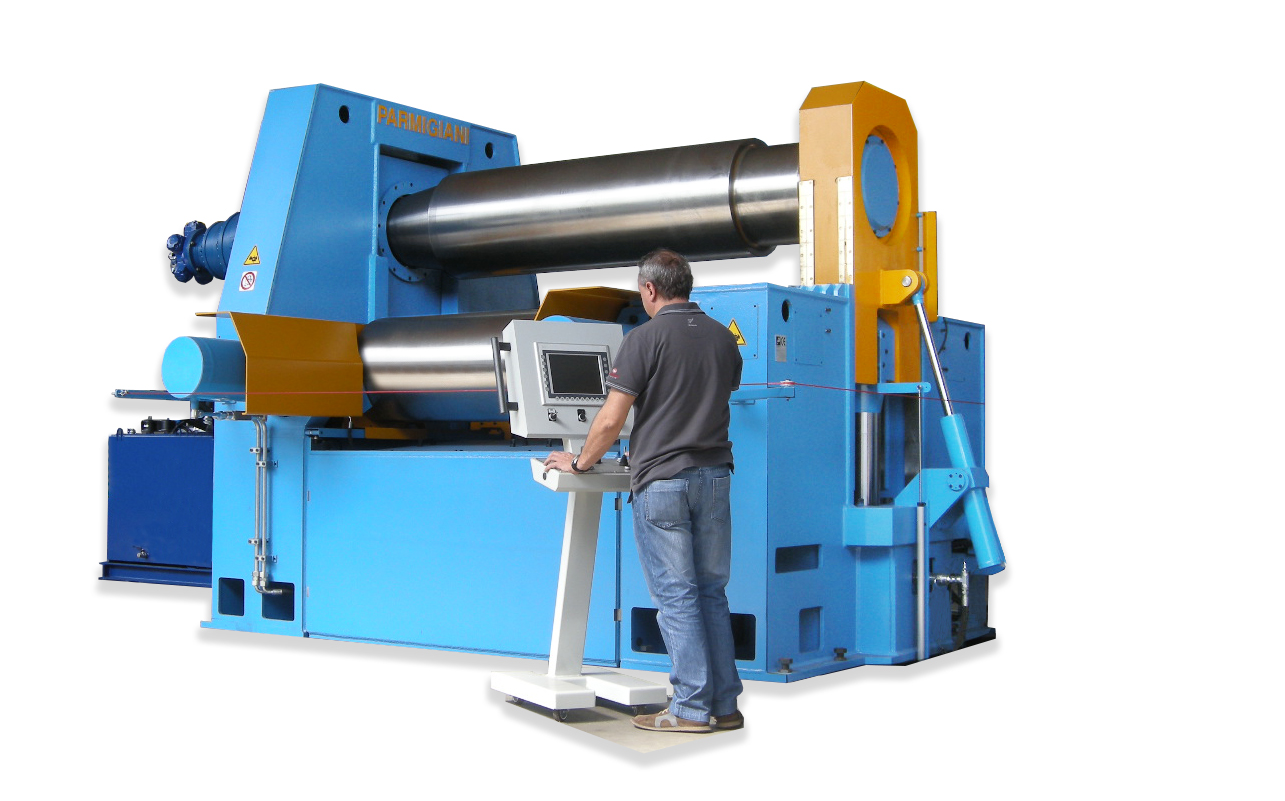

PCO Series – Walcarki 3-wałkowe

Bezwzględna precyzja gięcia wstępnego jest jedną z głównych cech naszej walcarki do blach PCO. Wszystkie trzy rolki poruszają się niezależnie od siebie, dolne rolki poruszają się po osi poziomej, górna rolka porusza się po osi pionowej. W ten sposób można regulować odległość między punktami gięcia i walcować blachy o dużej lub małej grubości.

- General Details

Maszyna PCO daje możliwość perfekcyjnego wstępnego zaginania każdej blachy,

pracując „jak prasa” i zawsze utrzymując blachę w poziomie,

co pozwala na prowadzenie operacji walcowania z pełnym bezpieczeństwem.

Maszyna wyposażona jest również w hamulce ostatniej generacji, które zapobiegają ślizganiu się płyty.

Rolki do blachy z serii PCO:

- Większa precyzja dzięki sterowaniu Hydrotronic

- Większa produktywność dzięki zsynchronizowanej mocy

- Mocna konstrukcja i specjalne funkcje

- Niezrównane możliwości toczenia stożka

- Najlepsze gięcie wstępne z maksymalną precyzją walcowania

- Inteligentne funkcje zwiększające produktywność

- Płynna regulacja prędkości

- Bezstopniowa regulacja siły gięcia

- Większa precyzja dzięki sterowaniu Hydrotronic

- Features

The peculiar geometry of the PCO roll makes it possible to bend big thickness plates just increasing the distance between the lower rolls, in this way it is possible to have a heavy duty machine with a smaller structure compared to a traditional 3 or 4 roll plate bending roll.

Plus the PCO machine need limited foundations even for big thickness plates due to the reduced working height.

Discover the exclusive features of the PCO Series:

- Rigid frame construction without forces transmitted to foundations

- The 4 hydraulic cylinders that move the lower rolls are allocated inside the frame

- Wired with light-cables against electromagnetic interference

- Centralized control panel, light weight design for easy handling

- Rolls made of high resistance steel forgings, with large diameter and light cambering

- Machine frame with linear guides for rolls sliding

- To ensure the maximum rigidity and strength of the machine the uprights are connected by two heavy-duty H-beams fabricated frames

- Sliding support with high resistance antifriction material maintenance free

- Fully hydraulic drive with automatic speed compensation

- Instantaneous brakes for rolls rotation for maximum safety factor

- Digital control of the rolls parallelism with proportional valves. Precision 0,1 mm (0,004”)

- Heavy-duty turning bearing support, with four anti deflection points for maximum rigidity

- Infinitely variable bending pressure of the top roll with digital pressure gauge

- Heavy-duty and rigid frame design for maximum resistance for cone rolling

Variable geometry Increased flexibility

The PCO allow to change the geometry between the bending rolls and this give at the operator the maximum flexibility to adjust the machine for a wide variety of rolling works (pre-bending, cone pressing, rolling, shell calibration etc….).

Lower rolls variable centerline

The possibility to adjust the distance between the two lower rolls increase the flexibility and the thicknesses range the can be rolled on the machine:

This allows to roll heavy wall thickness plates (max. centerline distance) while with the lower rolls very close each other (min. centerline distance) you will obtain an optimal plate feeding for thin plates.

- Technology

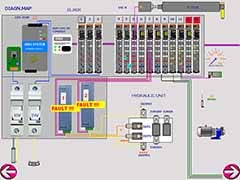

i-Diagnostic®

ACTIVE EXTENDED DIAGNOSTIC

Everything is under control Are you loosing with your actual equipment production hours and days checking around the machine which connection wire, Plc card, push-button or fuse is faulty?

Are you loosing with your actual equipment production hours and days checking around the machine which connection wire, Plc card, push-button or fuse is faulty?Forget this kind of problems with PARMIGIANI i-Diagnostic system for immediate fault detection.

The i-Diagnostic is a revolutionary diagnostic system that supervises all the main functions of the machine, with an easy to use and intuitive control panel interface.

From the screen you control almost all electrical connections around the machine; all PLC modules; all micro-switches (You can check also if they are engaged /energized or not) and more….

Instantaneous fault detection instead of troubleshooting

Detailed information on type and location of the faultPPS Hydrotronic®

PARMIGIANI PARALLELISM SYSTEM

Lifetime precision When you want to move to precision rolling, look to Parmigiani

When you want to move to precision rolling, look to ParmigianiThe PPS is the most advanced parallelism system today available on the market.

The rolls parallelism in a plate bending machine is the key factor for the production accuracy.

The capability to maintain the precision across the years is also another critical point.

For this reason we employ the best of the today available technology: digital control system and hydraulic flow control via proportional valves.

We have designed a system totally insensible at the wear that will give you years and years of trouble free operation, keeping the machine positioning precision like the first day!

The top and bottoms rolls parallelism is fully controlled by a digital “high speed” FIELD BUS system.

The package includes also a set of hydraulic proportional valves with high performance digital control cards, matching the high speed of the FIELD BUS system.

This digital technology (the loop control is 20 times faster than PLC-based electronic controls) joined with the hydraulic proportional valves, provides a parallelism precision of about 0,1 mm.

Digital control technology with hydraulic proportional valves

Parallelism precision 0,1 mm

FACILE®

ADVANCED WIRING SYSTEM

Plug and play technology

Do It by yourself

“Assemble and plug in – that’s all!”

Quick and simple plug connections replace elaborate wiring.

- Avoids wiring errors

- Shortens start-up time

- Quick swapping of cables

The wiring of the machine is achieved by Plug and Play connectors and digital distributors.

The cabling system with connectors is more reliable over time, totally insensitive to environmental contamination and vibration and allows for quick and easy maintenance with unqualified personnel

With our FACILE® Plug and Play system you can change a wiring connection (to the hydraulic valves or the encoders or potentiometers, to a micro-switch etc…) with pin plug connector, without unscrewing any electrical wire.

Same procedure for all PLC modules! Without the need of a skilled electrician!

With the purpose of increasing your independence from third parties all software are loaded in static memory cards, (like the ones used in digital video camera) and not in volatile Eprom! This means practically that you will never lose the software, even in case you will need to change the Plc unit.

Our plug-play system is a military approved technology!

Maximum reliability.

Quick and easy maintenance without specific skill.

Hi-Tech Hydraulic

ADVANCED HYDRAULIC SYSTEM

Infinitely variable adjusting speeds

Infinitely variable bending pressure The hydraulic system is the operative core of your VBH: it runs everything from the bending rolls drive to the bending rolls movement, tilting and all other machine attachments.

The hydraulic system is the operative core of your VBH: it runs everything from the bending rolls drive to the bending rolls movement, tilting and all other machine attachments.This is why we invested a lot in research and development, for give you a smooth, precise and highly responsive system.

Through the digital control system we control, by dedicated hydraulic proportional valves, the pressure and flow in order to allow you to select the most convenient speed during each production step (vs. other brands machines that give you only one or two selectable speeds) and the maximum central lower roll pinching force in order to adapt it to the characteristics of the plate being worked.

The possibility to select low pressures for thin plates widely extend the range of the machine.

With the infinitely variable pressure and the infinitely variable speed adjustment the operator will have full control of the process in any bending situation.

- Options

Rolls induction hardening and heat treatment.

Rolls induction hardening and heat treatment.- Cone bending device.

- Fully hydraulic upper plate support device.

- Fully hydraulic side plate support devices.

- Motorized in-feed roller tables.

- Small diameter interchangeable top roll.

- Heat exchanger for cooling the hydraulic oil.

- Increased (Turbo) rolling speed.

- Machine special design and protection for hot rolling.

- NC control: SAVE&BEND.

- CNC control: FAST and STRADIVARI 3-R.

- Wireless control.

- Special operating voltage or special electrics.

- Remote assistance via modem.

- Gallery