Q25

These are often heavy and/or large steel plate parts, which need to have a large edge radiused on both sides to ensure good adhesion of the powder coating. These parts must be fed through the machine twice and reversed in between. The latter is often done by hand or with the help of an overhead crane. This is time-consuming, strenuous work for the operators and not completely safe. Because Q-Fin’s GrindingPower philosophy is that products can only be given a large radius on one side at high speed, Q-Fin has developed a reversing station in 600, 1200 and 1500 mm widths.

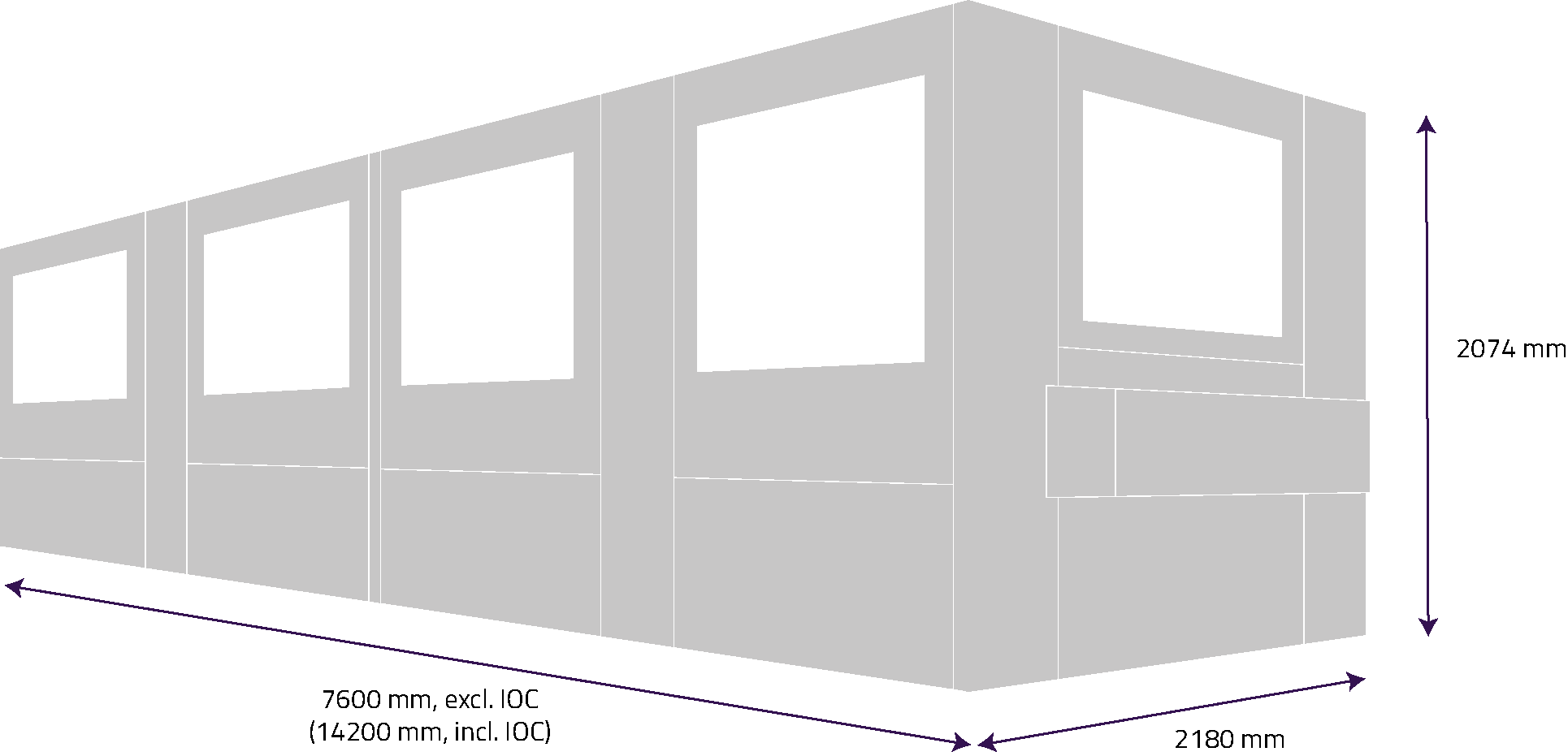

The Q2S turnaround station, integrated in the deburring line, provides double-sided processing in batches at an unprecedented high throughput rate. The system can be managed by one operator. The Q2S system standard includes 2 pieces of IOC input/output conveyors.

“We only need the best production machines to be able to guarantee our own quality. The Q-Fin deburring line is suitable for large sheets which are difficult to turn by hand because it turns them automatically. That saves us a lot of time and money.”

Bram Willems

Chief Operating Officer at Willems Baling Equipment

Available as Q2S600 – Q2S1200 – Q2S1500

Maximum conveyor load: 550 kg

Minimum product thickness: 1,5 mm

Maximum product thickness: 50 mm

Minimum product dimension: 280 x 280 mm

Voltage: 3x400V+N+PE / 50 Hz