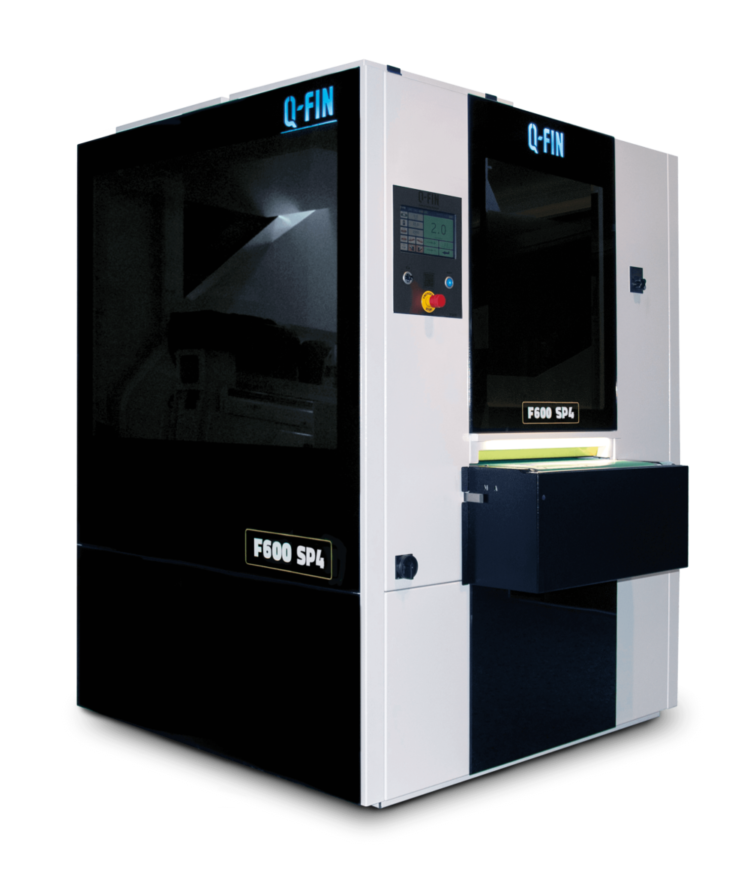

F600 SP4

The F600 SP4 is a 600 mm wide machine with a planetary brush system. This deburring and finishing machine is equipped with 3 processing stations: a grinding station followed by 2 + 2 planetary heads. Each planetary head is fitted with 4 counter-rotating bowl brushes, so the machine is equipped with 16 bowl brushes (⌀ 155 mm). The oscillation of the 4 planetary heads gives you unrivalled finishing possibilities with this machine. You can use this machine to perform a variety of finishing operations including deburring, rounding and finishing.

The F600 SP4 is the ideal machine for finishing sheet metal parts up to 600 mm wide.

With cutting processes such as laser cutting, plasma cutting and water jet cutting, burrs can occur on the metal workpieces. These sharp, protruding imperfections are undesirable for multiple reasons. Deburring is therefore necessary to remove them.

Q-fin has developed an innovative machine line for the mechanical, fast, proper and easy deburring of steel, aluminium and stainless steel sheet components. Hence, there is always a machine that deburrs your product(s) in a satisfactory manner. Against low costs, with a high speed and easy to operate. The machine can of course also be used for removing burrs as a result of other processes such as cutting, sawing, punching and/or stamping.

Grinding is a machining technique whereby material is removed with the use of an abrasive belt or grinding disc. With grinding you can remove burrs from a product, remove imperfections or apply a specific abrasive structure to the material.

To remove damages, small indentations and a hard mill scale, often coarse abrasive belts or grinding grains are used, for example a Grain 40 (G40) or a Grain 60 (G60). When all imperfections are removed from the metal, it is possible to apply a surface finish. A frequently chosen finish is the G320 grain, a nice and neat abrasive structure that is also much smoother than the G40 or G60.

At Q-fin we have both manual and fully automatic grinding machines. We gladly advise you on the right machine for your grinding operations.

Most customers require edge rounding or at least edge breaking of the edges of metal workpieces. Otherwise, the staff members in manual assembly processes and end-users may injure their hands. Therefore, they must be extremely careful when manoeuvring the workpieces, so they cannot work quickly. Often customers provide specifications for a certain consistent radius to the product.

Depending on the objective, Q-fin can, with its machines, assign a constant radius in one passage by breaking or rounding edges in accordance with the requested radius. We ensure an optimal configurable edge rounding.

Q-fin offers you standard a combination of deburring, grinding and edge rounding in 1 machine.

Grinding is possible at multiple gradations of roughness. The roughness value of the product surface is indicated by a number. Generally, the average roughness is considered for this purpose, indicated with ‘Ra’. The desired roughness is related to the application of the product. Whether it should be free from attached micro-organisms, whether it is a visible object or not, etc.

At Q-fin we have machines for the grinding at every desired roughness and in accordance with all customer specifications and prescribed requirements and standards. By means of a demo at our company in Bergeijk we gladly show you everything that we are able to achieve.

Line grain grinding, also known as a line grain finish, is the most common finish for metal, especially for stainless steel. Stainless steel components with a line grain finish are often used for visible work: products such as extractor hoods. Usually a grain size is indicated for grinding, that indicates how finely the surface is grinded. The higher the number, the finer the grain. For example, G320 stands for a 320 grain.

With the machines of Q-fin you can give products of 10 mm wide up to 1200 mm wide the grinding structure you choose, from G40 to G320. A finish with Scotch-Brite is also part of the possibilities.

“We noticed that there was a lot of demand for well-finished sheet metal parts from our customers. They can achieve a much higher level of finish with these parts and they save a lot of time compared to when breaking edges and rounding them off with a handheld grinder, for example. We are pleased to see that in this way we can also contribute to the quality improvement that is taking place at our customers.”

– Erwin van Soest

Director at Erba Plaatbewerking B.V.

– Conveyor belt speed adjustable: 0.3 – 8 m1/min

– With vacuum or magnetic support

– 4 pcs. 2,2 kW brush motors with frequency control

– Min. workpiece dimension: 50×50 mm (MAG) / 80×80 mm (VAC)

– Maximum workpiece width: 600 mm

– Maximum workpiece height: 150 mm

– Machine power supply: 400 V, 50 Hz, 32 A, 16 kW

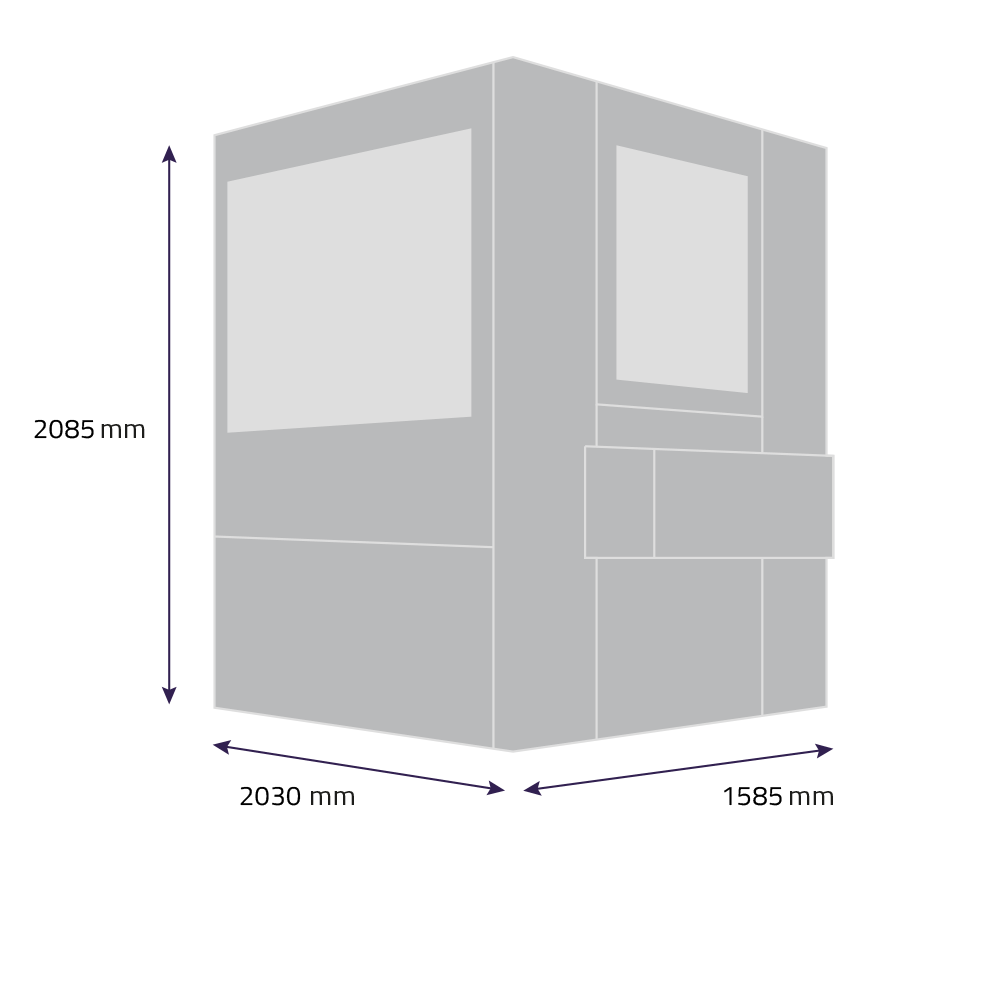

– Dimensions: 2030 x 1585 x 2085 mm (L x W x H)

2,150 KG

2,150 KG